|

|

| Technical Data | August 2006 |

|

|

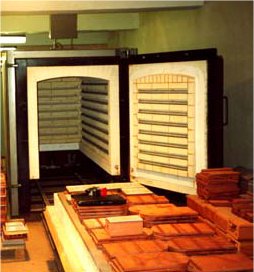

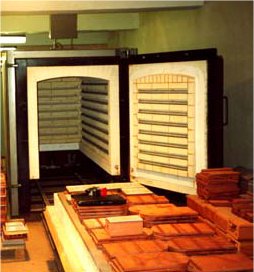

GENERAL DESCRIPTION:

WKB series kilns have an inner "heat box" surrounded by an air gap set in a steel outer casing.

The working insulation face is lightweight insulating firebrick for resistance to mechanical abrasion and chemical erosion. The door is side hinged to allow the removal of the kiln hearth. The hearth trolley runs on rails so that it locates exactly into the furnace sides providing a good heat seal. Because the door is on the furnace the hearth can be loaded from any direction.

A sheathed thermocouple within the chamber gives accurate temperature sensing.

The electrical controls are mounted in a box to the side of the kiln case. Temperature control is achieved through a separate unit connected to the control box by a flexible cable and normally attached to the side of the kiln near the door for easy operation. The temperature controller incorporates thermocouple break protection as standard.

A choice of PID digital controllers with digital setting and readout are offered. A door safety switch is fitted to all models. Various optional extras are available.

| Product | Max Temp°C | Internal Dimensions (mm) | Volume | Power requirement | Weight | ||||

|---|---|---|---|---|---|---|---|---|---|

| Width | Height | Depth | Litres | kW | Volts | kg | |||

| WKB 800 | 1260 | 740 | 1200 | 1000 | 800 | 60 | 400 3ph, N | 2500 | |

| WKB 1000 | 1260 | 760 | 900 | 1450 | 1000 | 75 | 400 3ph, N | 3000 | |

| WKB 2000 | 1260 | 960 | 980 | 2200 | 2000 | 110 | 400 3ph, N | 5000 | |

| WKB 4000 | 900 | 900 | 1100 | 4100 | 4000 | 150 | 400 3ph, N | 7000 | |

All kilns will operate on 415V 3ph, N, E, supply. Kilns can be supplied with 900, 1260 or 1280°C maximum operating temperature.

The above data is offered only as general performance characteristics and may alter due to mains voltage fluctuations and modifications etc. Dimensions are in mms.